LEVIS’ goal is not only to produce innovative lightweight materials for a selected number of key (electric vehicle) components, but also to approach the design in a ‘circular manner’. In other words, to consider the principles of circularity through an adopted eco-design method and consider the full life cycle of these components. To accomplish this, project partner Cenex Nederland (CENEX NL) developed and, together with industrial partners, trialled the iEDGE toolkit (integrated Eco-Design Guideline and Evaluation). Its purpose is to better support and guide the decision-making process in the early stages of a product’s design. The toolkit was used by the EV component manufacturers within the LEVIS project. The iEDGE toolkit helps the user(s) to identify the impact of current market solutions over its entire life cycle. This information can be used in the toolkit to set requirements and explore creative, out-of-the-box solutions which tackle key bottlenecks, ultimately arriving at a design strategy which is in line with the company’s larger vision and objectives.

How does it work?

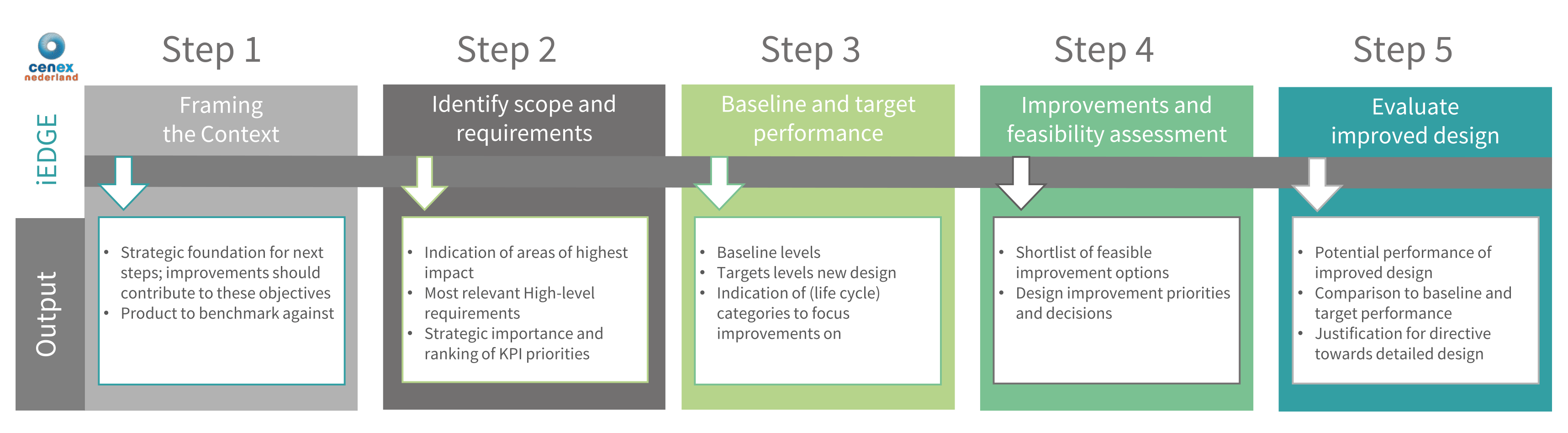

The toolkit can be used broadly as it is not developed solely to cater for components in the LEVIS project. Unique about this toolkit is the integration of environmental, economic, technical, and social focus areas. Integrating these four cornerstones of product design requirements makes sure that environmental responsibility is not seen as a separate isolated consideration during the design process. It helps to facilitate a balanced trade-off between the different considerations and requirements with regards to the impacts and improvements that are being considered. The exercise consists of roughly five main steps:

The tool’s results for the demonstrators

The iEDGE toolkit was developed in collaboration with the industrial partners, LEAR, MERSEN, MARELLI, YESILOVA and TOFAS (and feedback from other partners). All the demonstrators identified improvement options, focusing on KPIs that were of high importance and often linked directly to the strategic objectives of the company. They also gained a better overview of the relation to the different life cycles categories as well as finding a balance between the four focus areas (or cornerstones): environmental, economic, technical, and social). The selected improvement options are expected to achieve significant improvements in comparison to their respective baselines in multiple life cycle stages. The design improvements did not always meet the targets they individually set and indicates there could still be room for improvement or that the targets were set quite ambitious. The outcome of the exercises confirms that Lightweighting is not merely about ‘making things lighter’, but means considering the broader effects of design choices, affirming the approach by LEVIS to include eco-design and circular economy principles.

The intermediate and final feedback from the various partners during the process was instrumental to the tool’s value and making it easier to use. And although the exercise does require some additional investment in time, the overall opinion amongst the partners of the iEDGE toolkit’s value was a positive one. The fact that partners showed interest in using the iEDGE toolkit in future projects validates the approach of integrating eco-design into the larger design process. If you want to learn more details about the whole process and the individual results you can download the corresponding deliverable report here.

What’s next?

In collaboration with the other partners, CENEX NL will now embark on the more extensive and detailed LCA assessments, first for the benchmark settings and later, once the detailed design and processes are fully defined, for the new designs. In addition, we will dive into Life Cycle Costing, opportunities for further application of the material/process innovations and more.

CENEX NL translated their circular economy and eco-design expertise through the LEVIS project into a practical toolkit and guideline and aims to build on this further. Interested in applying this methodology into your design process? Don’t hesitate to get in touch.

CONTACT

Floris Teunissen

Assistant Technical Specialist | Cenex Nederland

+ 31 (0) 20 36 99 883

floris.teunissen@cenexgroup.nl